"aberson Bresident of the FullyAssed Committe" (emaxxbl)

"aberson Bresident of the FullyAssed Committe" (emaxxbl)

07/30/2014 at 13:49 • Filed to: oppo school, welding

6

6

6

6

"aberson Bresident of the FullyAssed Committe" (emaxxbl)

"aberson Bresident of the FullyAssed Committe" (emaxxbl)

07/30/2014 at 13:49 • Filed to: oppo school, welding |  6 6

|  6 6 |

TODAY i will teach you how to weld

well a little bit to get you started

this is a this is a baby's first welder if you will. It is a gas-less electric MIG welder

what do all those words mean you ask?

well it simply means that it uses electricity to melt everything together.

But more on this later, before you can weld you need to know your tools, metal, and location.

First up is the tools

This is a welding torch/gun it is the most important part of the welder, It has one button with one setting. You press it and welding rod will come out the tip. Everyone welds differently but i like to have around 1/8 inch to 1/4 sticking out. The more that sticks out the faster the weld puddle will grow in size and heat.

This is the grounding clamp for electric welders, what this does is complete the circuit from the welding torch into the metal and back into the welder. It is critical to have a good ground or your welds will be sporadic and inconstant.

How do you hook it up you ask?

its simple grab it like you would jumper-cables and attach it to a piece of the metal your welding

-picturehere-

Now that i hooked it up i can start welding right?

NOT SO FAST, we haven't gone over the most important tool yet!

the welding helmet.

Now most welders will come with cheap welding masks, I hate them because its too much hassle to have to lift up your mask every time you need to see your welds, and it makes it even harder for beginners to weld because you have no way to tell the relation between the torch and the metal because they are always tinted unlike an auto-darkening helmet.

This is a solar powered auto-darkening helmet. Remember how i said its important to know all your tools?

This is incredibly important in relation to the helmet because not all helmets are suitable for all types of welding for example the helmet i have is a cheap $50 one that is only useable for non-gas MIG welding, most helmets will have a label somewhere on the packaging/inside of the helmet saying what it can be used and not used on.

Now your probably asking about welding gloves and a welding jacket.

well for backyard MIG welding jackets will be unnecessary most of the time and gloves will be more of a personal thing, Personally i don't use them unless i have to.

Now if your going to be welding something while your under it and your going to be directly in the spark-shower then yes you should be wearing gloves and a jacket.

Ok NOW i can start welding right?

NO, you still need to know about you metal.

Why is this so important you ask?

Because most of the time MIG welders are only suitable for hard metals like steel.

But that's the only reason. Sometimes some metals shouldn't be welded because they can be dangerous, like zinc for example.

Zinc emits a poisonous gas when welded

But i don't use zinc. who even uses zinc for anything anymore?

Well zinc is a prime ingredient for galvanizing

so don't weld galvanized metal unless you want to DIE.

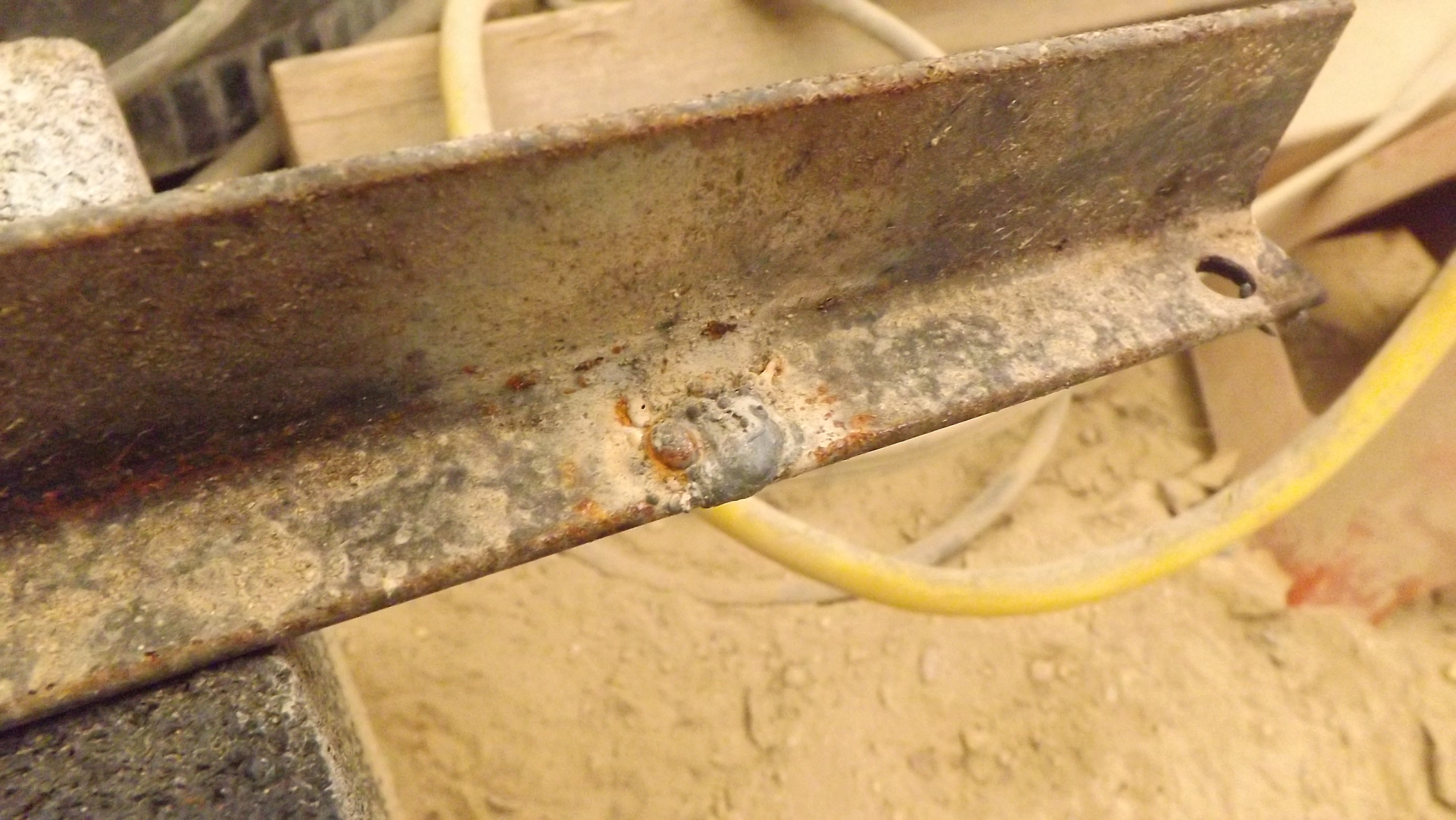

Now to show you i will be welding a piece of angled steel

as you can see its quite thick

this was my practice piece so i've already started to weld it in some places.

they're not the best but they're not the worst either.

Ok now that i know about my metal and you've showed my some of your welds i can start welding right?

NOPE

you forgot about location, not only is it important to weld safely but you need to be comfortable too.

NEVER, NEVER, NEVER weld near flammable containers and always make sure your in a position where you feel safe and comfortable, if you don't feel safe don't weld, simple as that. Also if you can't control you environment around you then either don't weld or move to a place where you can control your environment and ALWAYS KEEP PETS AWAY. :(

Can i weld now?

not yet. we still have to take a closer look at the welder, and the general techniques to welding.

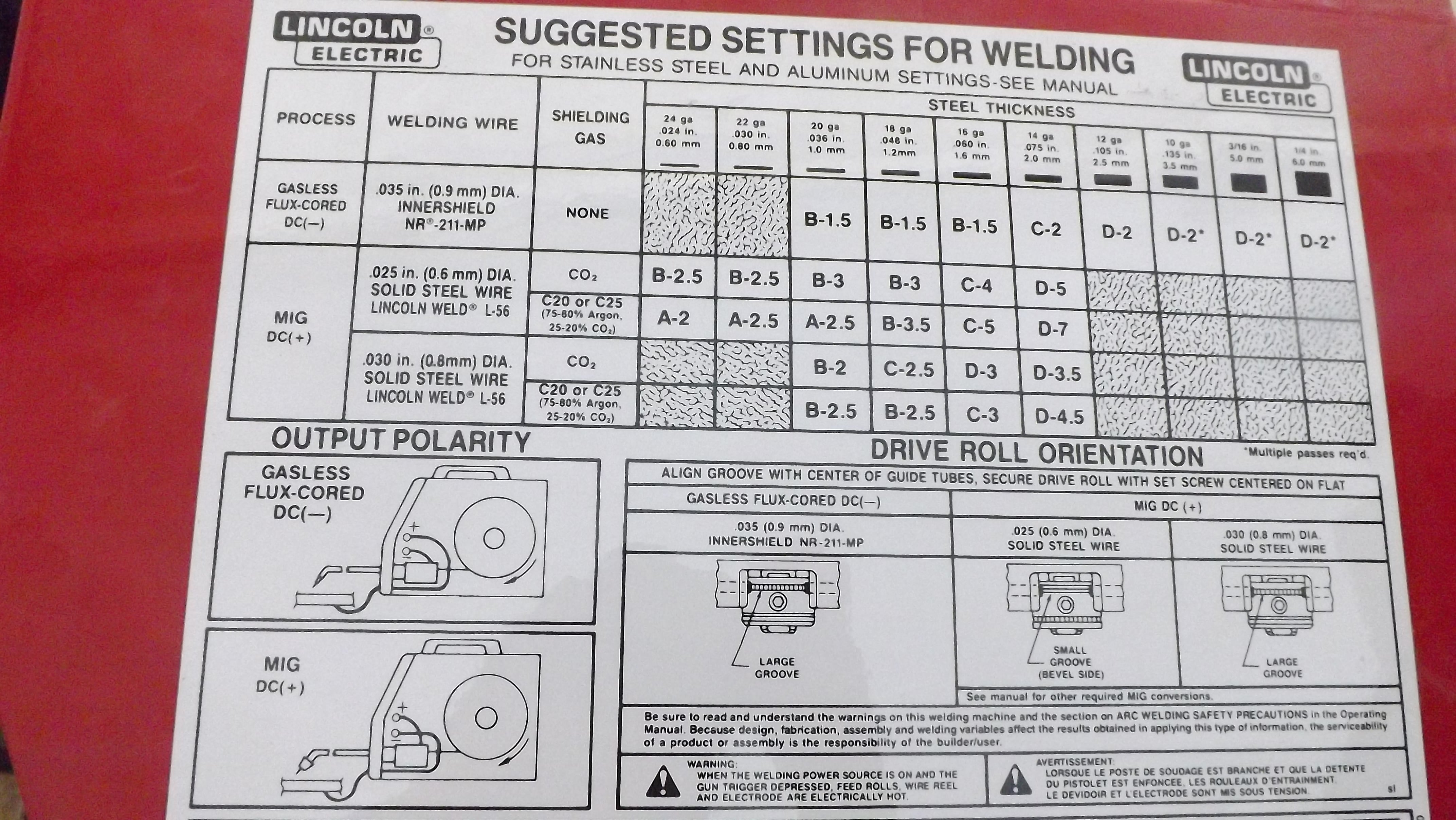

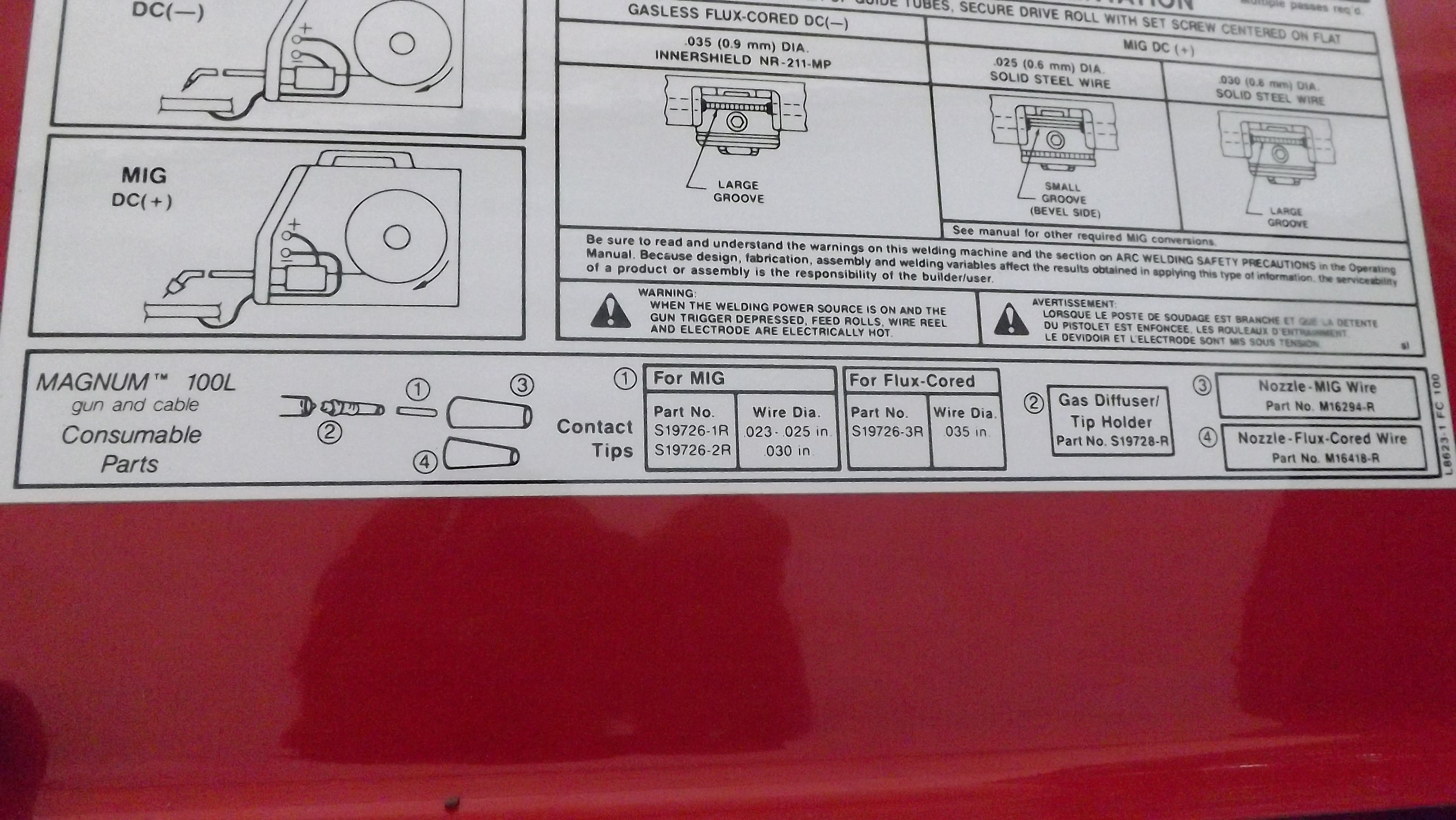

Now onto the welder

As you can see it is incredibly simple there is a on/off switch and two knobs

The top knob is used for how fast the welding rod comes out, which will effect how big the puddle gets, the higher the number the faster it comes out

the bottom knob is used for how much electricity flows throughout the weld, the higher the letter the more current flows through and it will weld faster and hotter.

There is even a label on the inside of the welder to tell you the specs you should use.

Ok so now i can weld?

YES well kind of

we still have to go over the general techniques

Always keep the torch steady and close but not touching the metal itself and try not to let out more rod then you need.

First you will start off with spot welding or booger welding as it is commonly referred too

try to focus on getting the bead on the metal and not piling it up too high and play around with the different settings see what they do and how it effects the welds.

and then later you can focus on filling in holes and trying to get a contentious bead.

Remember reading this won't make you a master but it will help you get started/be a better welder

A perfect weld should be strong yet still small and should not interfere with the feel of the metal too much, it should look like the weld has been melted into the metal.

not a perfect weld but you get the idea.

Remember welding should not be frustrating stay calm and take breaks and do research and see what your doing wrong.

this was the longest post i've done

Alfalfa

> aberson Bresident of the FullyAssed Committe

Alfalfa

> aberson Bresident of the FullyAssed Committe

07/30/2014 at 14:01 |

|

Personally, I would recommend always wearing gloves, jacket and denim pants when welding. Shit happens, and molten metal is not something you want on your skin.

tromoly

> aberson Bresident of the FullyAssed Committe

tromoly

> aberson Bresident of the FullyAssed Committe

07/30/2014 at 14:06 |

|

Flux welders, in general are far inferior to a proper gas-shielding welder. Just food for thought.

Bandit

> aberson Bresident of the FullyAssed Committe

Bandit

> aberson Bresident of the FullyAssed Committe

07/30/2014 at 15:27 |

|

I've both arc and flux welded but I'm not that good. I always wear gloves, I'm too big of a pansy to not wear them.

aberson Bresident of the FullyAssed Committe

> Alfalfa

aberson Bresident of the FullyAssed Committe

> Alfalfa

07/30/2014 at 19:50 |

|

definitely safety always comes first its just that with my size hands gloves become a burden because most that i've tried have been too big/small so i really only use them when required

aberson Bresident of the FullyAssed Committe

> tromoly

aberson Bresident of the FullyAssed Committe

> tromoly

07/30/2014 at 19:51 |

|

they make nice welders when you need to do a small weld quickly

though i do agree they're really outdated now

Alfalfa

> aberson Bresident of the FullyAssed Committe

Alfalfa

> aberson Bresident of the FullyAssed Committe

07/30/2014 at 20:23 |

|

I would day it's definitely worth it to find a pair that fits. Maybe I'm just a stickler because I work in the occupational safety industry, or because my first welding instructor had an electrode up his ass, but one accident may be your only one.